2024 Japan Obon season is coming

Many companies are close for Obon season …

is the renamed company of Imai Seisakusho Co., Ltd. which has been in customized machineries manufacturing business in industrial use for more than 60 years in Japan.

Having half of design engineers and production engineers with experience of more than 20 years, we are proud that we can devise customized machineries as customers request with high quality and reliability.

For more than 30 years, our main products have been cleaners and cure ovens for glass panels used in production of LCD panel, Solar panel, OLED and so on.

Due to our rather long experience, so far we have made wide range of these machineries. In terms of size of panels to be cleaned, such machineries we have made so far were from 20 to 3,400 mm of length or width with glass thickness of 0.1 to 15mm.

Size of particle (dust) to be removed by those are from 10 to 1 micron millimeters.

Basic tools of cleaning are brushes (roller or disk type) and water jet. And as the dust size to be removed goes smaller, other tools as high power water pressure, ultrasonic, megasonic, excimer lamp are to be equipped.

Price range of these machineries goes from around 100 thousand to 3 million ?US dollar.

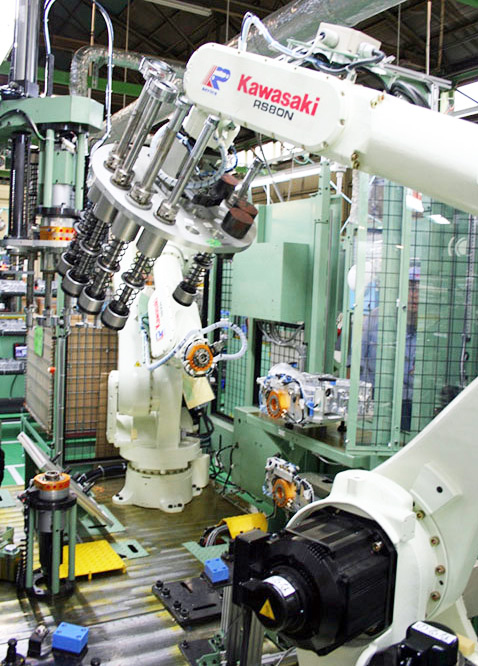

Cure ovens we dealt with so far are often combined with robots to input and take out panels to and from ovens automatically as programmed time elapse.

Our worldwide customers in this area are as follows.

Asahi Glass, ULVAC, Hitachi, Toshiba, Sony, Canon and so on in Japan, Samsung and LG in Korea

AUO, Innolux and others in Taiwan

BOEOT in mainland China

Philips in Holland, OSRAM in Germany and 3M in Sweden.

The next of our 4 products range is material handling conveyor system. Now we are focusing on exploring customers of these machineries outside Japan, mainly in Europe and in the rest of the world. Material handling conveyors application we can cover are such as food and beverage industries, cosmetics, medicine industries and almost any area of daily products.

Our strength in this area is that we can newly develop those devices as customers request within existing configurations through close discussion with customers based on our experience and knowhow.

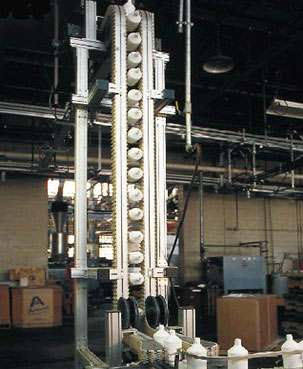

As an example, Friction Top Chain Conveyor is the real vertical conveyor as compared with ordinary vertical conveyors which may not be vertical in true sense of words. It has been realized by precise combination of grip between chain and roller, and between chains.

Also grip conveyors for bottles is rather unique conveyor we can provide.

Our typical strength is that we can manage to device conveyor system in the existing available space.

As the example, when the conveyor needs the space of 1 meter by 5 meters with traditional conveyors, the vertical conveyor can do by the space of 1 meter by 1 meter.

Our customers in this area are as follows.

A. Vertical conveyors??

1.Pouch products (cosmetics, pet foods, retort pouch and so on)

-Kao Corporation, ?INABA Foods Co., Ltd.

2.PET bottles for drinks

? Suntory Ltd., ?Coca-Cola Company,? Asahi Inryo

3.Film bag products for such as medical application as intravenous drop

-AY PHARMACEUTICALS CO., LTD

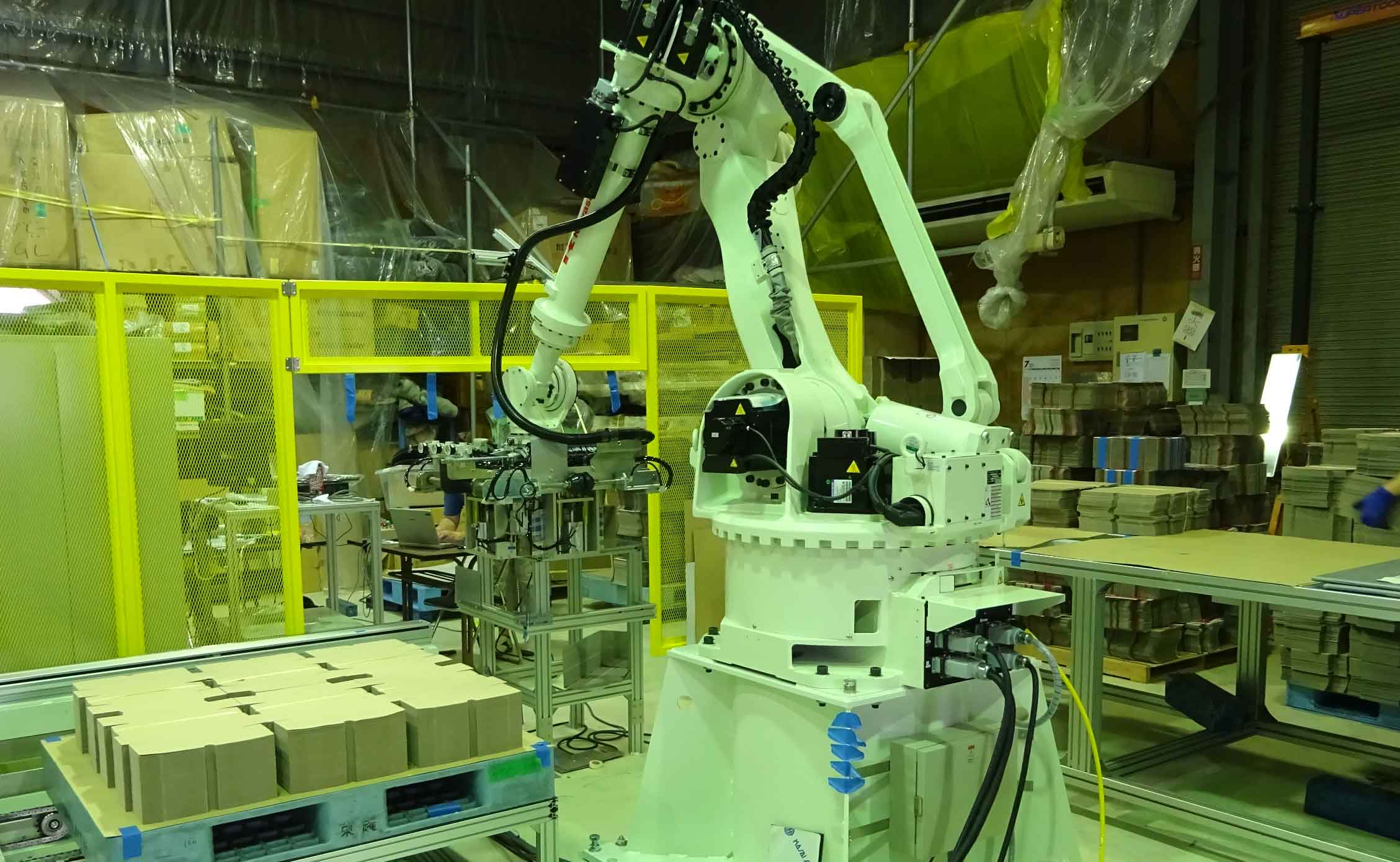

B. Conveyors with Robot

1.Palletizer (Cardboard box, other container boxes and so.on)

-Rengo Co., Ltd., Tomoku Co., Ltd., Nippon Tokan Package Co., Ltd.

2.Handling (Glasses, Automobile Parts, Medical Syringe and etc.)

-Hitachi Ltd., Toyota motor Corporation

C. Other Horizontal Conveyors (for almost anything such as food, drinks,

?? daily goods, automobile parts and all manufacturing products.)

1. Roller Conveyors

-Kureha Corporation, Kawasaki Heavy Industries

2. Belt Conveyors

-Kao Corporation, Kagome Corporation, Tomoku Co., Ltd.

Another category of our product is roll to roll machineries, which includes film roll unwinding and winding mechanism, and various treatment on the film, such as surface cleaning, chemical processing on film as etching, plating, and so on.

Application of such film roll are touch panels, LCD, PC, mobile phones,? on-board equipments, secondary battery with flexible circuit base, and so on.

Our experience in the width of films runs from 1 to 850 mm, and the thickness of films runs from 12.5 to 300 micron meters.

In ordinary arrangement such machinery is made for film to run horizontally

but unusual configuration to run the film roll vertically is in our experience.

Machineries of this kind is as large as 20 meters in length for test unit and goes to over 50 meters for production unit. The price image of these machineries are over 100 million USD for test unit.

Our customers in this area are as follows.

Konica Minolta, Inc., Toppan Printing Co., Ltd., Sumitomo Electric Industries, Ltd., Tokyo Ohka Kogyo Co., Ltd and others in Japan

The last category of our machinery is chamfering unit to remove the sharp corner of flat panels made of various materials as glasses, ceramics, sintered iron and quartz. This machinery is often combined with various cleaners.

This machinery is relatively new for us but the development of this machinery has been transferred to us from the original company which has been in this design and manufacturing for over 40 years.

Many companies are close for Obon season …

Our “Golden week” (not golde …

We will be closed for year-end and new y …

Now we would like to introduce our verti …

The topics we would like to bring now is …

This time we would like to introduce our …

The topics we would like to bring this time is the film roll cleaning machinery.

This time, we would like to introduce ou …