Vertical Glass Cleaner

Now we would like to introduce our vertical glass cleaner.

Ordinary glass cleaners are designed to place glasses horizontally on conveyors through cleaning process. But we have also made cleaners placed on conveyors vertically.

The advantage of vertical cleaner is that the width of the cleaner unit can be considerably smaller than horizontal type. In addition there is another advantage over horizontal layout cleaners. In case of vertical cleaners, the conveyor rollers contacts with glasses only at the thin edge. Therefore there will be no roller contact mark on the glass surface and particles generated from rollers are minimized.

The vertical cleaner we made was for the glass 1,400 x 1,100 mm with thickness of 3.2 mm.

Please contact us if you are interested in the vertical cleaners.

Cleaner for Solar Panel production

The topics we would like to bring now is the Cleaner for Solar Panel production.

We have ever delivered to customers more than 50 cleaners for Thin Film Solar Cell production in various production steps as the cleaner for the Panel Receiving step, cleaner before TCO coating, cleaner for After Patterning, cleaner for Final cleaning and others required by customers.

The cleaning tools we use are various, such as brushes, 2 fluids, medium pressure, high pressure and so on, according to the required cleaning.

We believe we can best contribute to customers in performance and productivity by choosing appropriate tools for cleaning.

Our cleaning tool can be also applied to compound type solar panel production.

We appreciate your inquiry.

PET bottle conveyor

This time we would like to introduce our conveyors for PET bottles (plastic bottles).

In this application, it is our standard design to use plastic chain. It must be the main concern not to cause troubles as PET bottle fall down or other accidents during the transfer from one conveyor to the other, or at bottle accumulator before liquid filling. We can design satisfactory conveyors based on our long experiences considering requirements for bottles to be conveyed and said troubles for specific PET bottle to be conveyed.

In case PET bottle conveyance includes up and down movement, vacuum conveyor can be a solution.

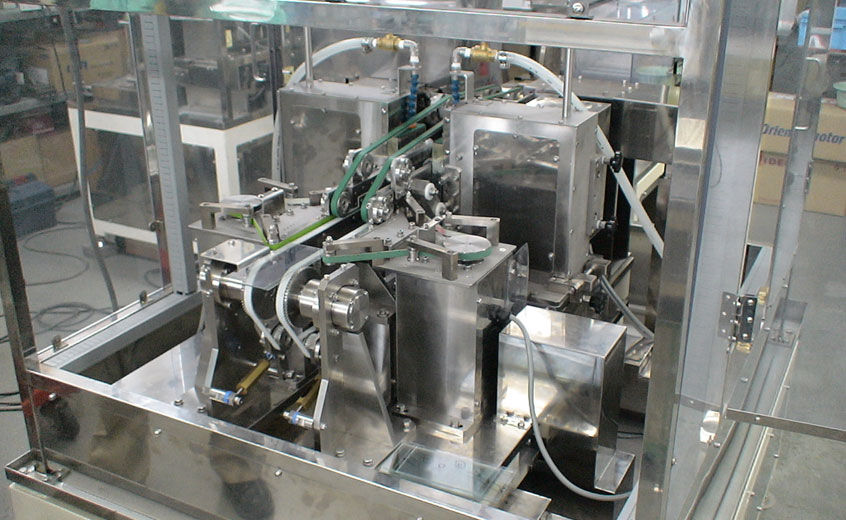

Roll to roll machinery

The topics we would like to bring this time is the film roll cleaning machinery.

The machinery is called roll to roll machinery, consisting of film loader (to send out the film), unloader (to take up the film) and cleaning and dryer unit in-between. The machinery is good for the film width as much as 600 mm and the thickness 0.05-0.3 mm. The cleaning tool can be UV, detergent, roll brush, ultrasonic, 2 fluids and so on depending on the required cleanliness, and dryer tool is normally hot air.

This roll to roll machinery can be used for other treatment of films as etching, development, plating and so on.

Please contact us for the treatment you would like to have on the film.

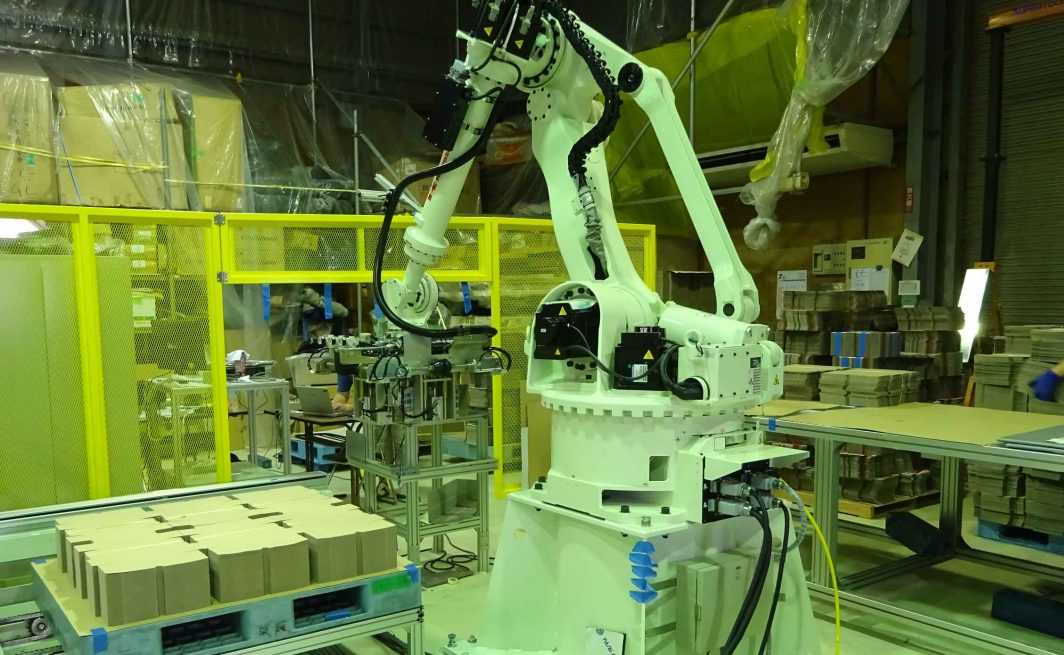

Robot Palletizer

This time, we would like to introduce our Robot Palletizer.

One of our conveyor system is the palletizer smartly controlled by the robot.

Incoming sheet of cardboards are placed in palettes according to the size of cardboards both horizontally and vertically as preprogrammed by a robot in the most efficient way in a palette. The robot can be supplied by the top ranking Japanese industry, Kawasaki Heavy Industry, according to the partnership agreement with our company (ICM ).

The choice of the robot manufacturer is, however, not limited to KHI but can be any as customers prefer.

Chamfering machine to eliminate sharp edges

This time we would like to introduce our chamfering machine.

Our chamfering machine can eliminate sharp edge of flat plates as glass, metal and ceramic panels. Chamfering of both top and bottom on one side can be done at the same time. By adding panel rotating machines, the sharp edges can be removed at all four periphery.

It can be combined with our panel cleaners so that the chamfered particles can be removed easily, otherwise hot particles scattered on the panel will be hard to remove when they are cooled down.

Please feel free to contact us on any detail you would like to know.

Glass cleaners for curved glasses in automobile application

This time, we would like to introduce our glass cleaners for curved glasses in automobile application.

Our cleaner is good to clean curved glasses such as windshield, side glasses, rear glass and roof top glass (can be called sun shield glasses, moon glasses and so on), by means of scrubbing brush and/or high pressure water jet. We actually supplied such cleaners for reinforced glasses and multiple layer glasses of 600 to 1850 mm width to automobile glass manufacturers.

Such adjustment as brush height, and as angle and height for air knife to remove water are automatically done by touch panel recipe. Not to mention, we have many experiences of delivering cleaners for flat panel prior to curving procedure.

We are glad to realize various requests by customers based on our long engineering experience.

Please feel free to contact us for any topics you would like to discuss with us.

Vertical conveyors system of 11 meter length

Recently we succeeded in developing the vertical conveyor with 11 meter vertical stroke for a food manufacturer.

This conveyor is used to bring down retort pouches (100x200mm,thckness of 18mm) from upper floor to lower floor, at the speed of 20 meters per minute by means of holding rollers against the moving conveyor.

Despite the long vertical distance, cross sectional area (opening of the conveyor) could be kept rather small, 1 x 1 meter. We believe this is a unique development made possible by our long experience in those equipment.

The thinnest substrate cleaner

In the previous issue, we reported the largest substrate cleaner ever in the world called G11 (Generation 11). The topics we would like to bring now is the thinnest substrate cleaner (if not the smallest). We successfully brought the substrate cleaner for the glass of 0.1 mm thickness. With the thin glass, we had to overcome the difficulty to run it through the conveyor without damage (breakage) of the glass.

G11 glass cleaner

Recently we successfully made the largest substrate (glass) cleaner ever and delivered to the customer (a big Japanese company).

The size of the glass to be cleaned is 3,000 x 3,400 mm with the thickness of 0.4-0.5 mm. This size is categorized as G(Generation) 11 and the largest ever made in the world. Engineering-wise, distortion of the system was a key issue to enable the cleaning of particle evenly all through the huge flat surface.

In the next news, we will be able to report the substrate cleaner for the thinnest glass on the smallest category.